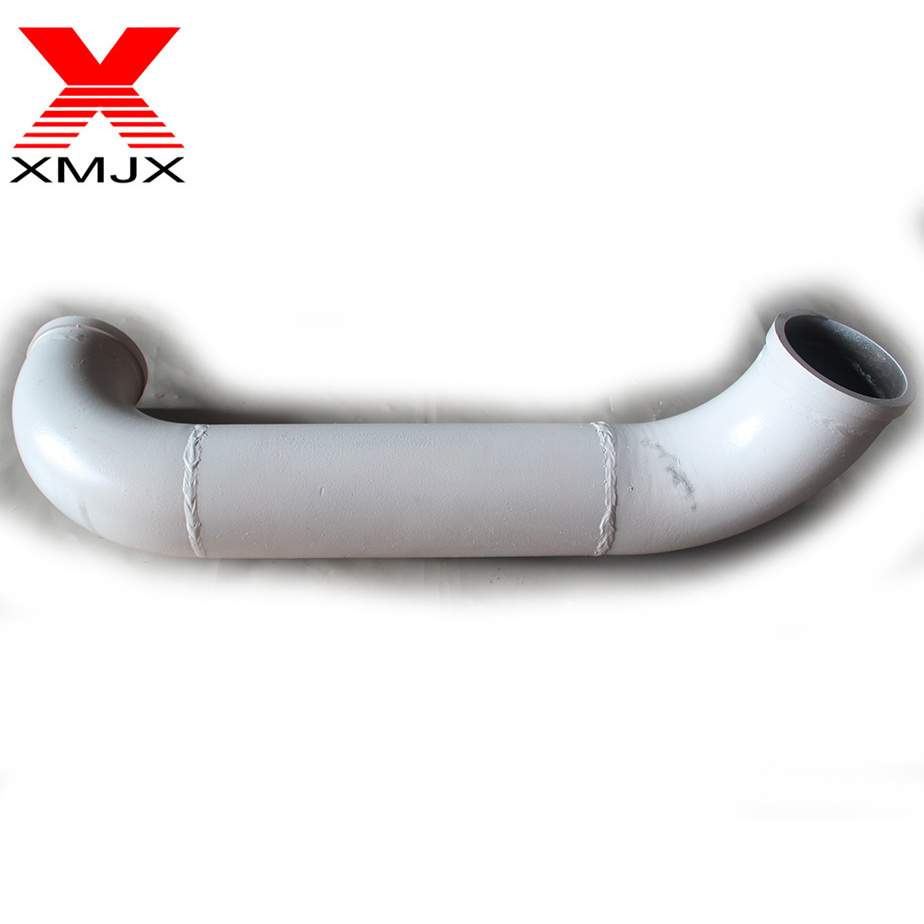

Concrete Pump Hot Forged 180d Elbow

Basic Info

| CONCRETE PUMP BEND PIPEDN150-6" | ||||

| Part NO. | ODIn./DIN | Center Line RadiusIn./mm | Degree ofAngle | Theoreticalweight(lbs./kg.) |

| BP1501445 | 6.0/ DN150 | 14/356 | 45 | 25.5/11.6 |

| BP1501490 | 6.0/ DN150 | 14/356 | 90 | 36.3/16.5 |

| BP1501845 | 6.0/ DN150 | 18/457 | 45 | 27/12.3 |

| BP1501890 | 6.0/ DN150 | 18/457 | 90 | 45/20.5 |

| BP1503245 | 6.0/ DN150 | 24/610 | 45 | 31.7/16.4 |

| BP1503290 | 6.0/ DN150 | 24/610 | 90 | 50.6/23 |

| BP1503245 | 6.0/ DN150 | 36/914 | 45 | 47/21.7 |

| BP1503290 | 6.0/ DN150 | 36/914 | 90 | 93.5/42.5 |

| BP1504845 | 6.0/ DN150 | 48/1219 | 45 | 60/27.2 |

| BP1504890 | 6.0/ DN150 | 48/1219 | 90 | 107/48.5 |

| Any type of elbow can be customized | ||||

| Any types of weld ends are available.METRIC (SK) WELD ENDSHEAVY DUTY WELD ENDSSCHWING F/M WELD ENDSPUTZMEISTER Z/X WELD ENDS | ||||

AdvantagesThe high quality structure ensures high abrasion resistance and toughnessManganese alloy iron casting enables the liner highly wear proof and reduce pressureSeamless welding enables the the outer layer hard to explodeLight weight improves vehicle efficiency, highly reduces labor and cost and the time for replacementDesigned structure, material and process realize its 3-5 times service life of common productsto extend the service life of other pipe fittingEasy to use and handleOur service………………………………………………………………………………………………………………………………………..

Production display………………………………………………………………………………………………………………………….

Product process…………………………………………………………………………………………………………………………………………

Product process………………………………………………………………………………………………………………………………………… Product test……………………………………………………………………………………………………………………………………….

Product test……………………………………………………………………………………………………………………………………….

Packaging&Shipping……………………………………………………………………………………………………………………………….