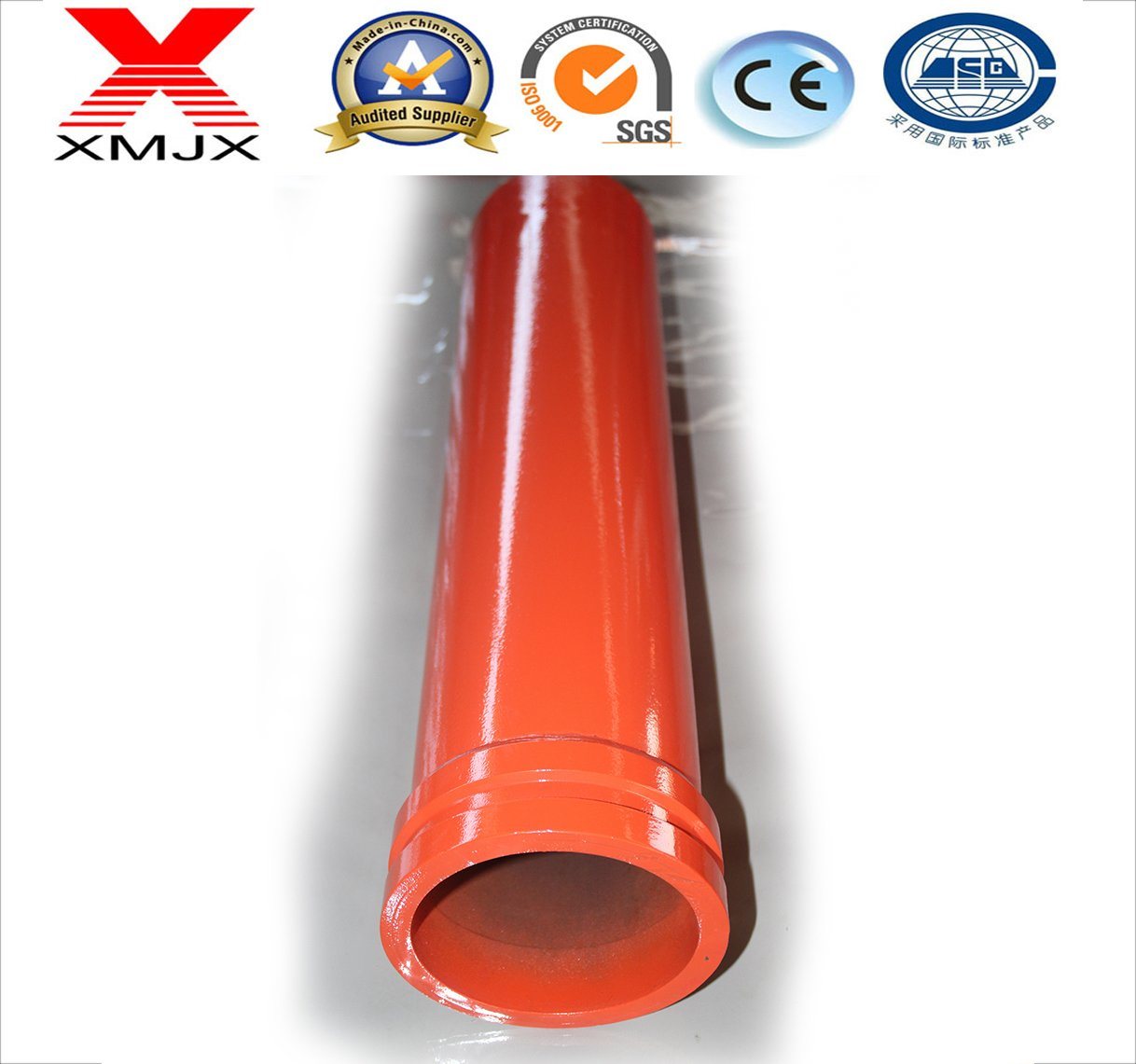

Line Pump Pipe DN125 -5" Seamless Pipe with Good Wear Resistance

Basic Info

Model NO.

DN125 -5"

Thickness(mm)

4~12

Length(mm)

1000~6000 or Customized

Flange Tape

Sk, HD, Zx, FM Flange Ends

Test Pressure

250bar

Surface Coating

Baking Paint

Length Deviation

+-1mm

Theoretical Weight(Lbs/Kg)

35/15.8

Weld Tensile Strength

>480bar

Color

Red Black White or Customized

Trademark

Ximai

Transport Package

Standard Export Package

Specification

M55 LINE PUMP PIPE DN125 -5"

Origin

China

| M55-5 | ||||||

| PRODUCT FEATURES | ||||||

| M55 LINE PUMP PIPE DN125 -5" | With SK, HD, ZX, FM Flange Ends | |||||

| Part Number | Thickness(mm) | Theoretical weight(lbs./kg.)/meter | LengthDeviation | TestPressure | WeldTensileStrength | SurfaceCoating |

| M55-540 | 4.0 | 28/12.7 | ±1mm | 160bar | >480bar | Painting |

| M55-545 | 4.5 | 31.5/14.3 | ±1mm | 180bar | >480bar | Painting |

| M55-550 | 5.0 | 35/15.8 | ±1mm | 250bar | >480bar | Painting |

| M55-560 | 6.0 | 44/19.8 | ±1mm | 280bar | >480bar | Painting |

| M55-565 | 6.5 | 47/21.4 | ±1mm | 280bar | >480bar | Painting |

| M55-571 | 7.1 | 51/23.3 | ±1mm | 360bar | >480bar | Painting |

| M55-591 | 9.1 | 65/29.4 | ±1mm | 360bar | >480bar | Painting |

| M55-5100 | 10.0 | 70/32 | ±1mm | 360bar | >480bar | Painting |

| M55-5120 | 12.0 | 84/38 | ±1mm | 360bar | - | Primer |

| Length=1000mmLength=2000mmLength=3000mmLength=3048mm(Length=120 inch, Length=10 feet)Length=4500mmLength=6000mm……..Any length and thickness can be customized. | ||||||

| Any types of weld ends are available.METRIC (SK) WELD ENDSHEAVY DUTY WELD ENDSSCHWING F/M WELD ENDSPUTZMEISTER Z/X WELD ENDS | ||||||

1.We are a professional manufacturer of concrete pump pipes in China.Our products include concrete delivery pipes,elbows,reducers,couplings,rubber hoses,cleaning ball and so on.2.Our products are top quality in china which have been used on SCHWING ,PM ,KYOKUTO ,SANY ,ZOOMLION ,CIFA,SINOTRUK(CNHTC),FOTON,XUGONG,CHUTIAN,HAINUO etc and have been recognized by them.3.The HRC of it’s inner wall can reach 60~68 and the serving life of it can increase 3~5 times.4.It is quenched and carried out carburizing chemical treatment on the inner wall.It has a high wear-resistant.5.OEM available from us.Our service.……………………………………………………………………………………………………………………….

High Quality:ISO9001, CE, CO certifications etc. All components adopt the qualified materials.100% quality check and durable testing for every product before shipment.Competitive PriceLarge scale production and well trained workers reduce cost greatly,Ximai use the Bottom Price to make you become the most competitive seller in your region.One-Stop ShoppingOur major is concrete pump pipe and forged coupling, we also have several partners,supplying related products so that can meet customers’ needs.Short Lead TimeWe have power production capacity, produce 1500 sets couplings and 500pcs pipes every day.We can have your urgent orders ready in short time.Standard export packageOur package is in conformity with export requirements.We ensure it’s very safe and firm in the course of shipping.Customer ServiceTop sales with professional skills make you never feel difficult to communicate with a factory,all Ximaistaff will stand by you, reply your inquiry and solve your problem, no matter pre-sales or after-sales.

Send your message to us:

Write your message here and send it to us